|

|

|

|

|

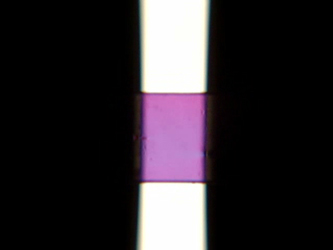

This rheo-optics video depicts the uniaxial extensional flow deformation

of a butyl rubber at 23°C being stretched at a Hencky strain rate

of 0.3 s-1 with no back light source, just linear polarized ambient light passing through

the mid-section of the sample. Note how the entire flow field can be visualized.

This rheo-optics video depicts the uniaxial extensional flow deformation

of a butyl rubber at 23°C being stretched at a Hencky strain rate

of 0.3 s-1 with no back light source, just linear polarized ambient light passing through

the mid-section of the sample. Note how the entire flow field can be visualized.

(AVI file format: 1.55 MB)

|

|

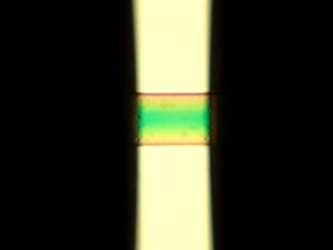

This rheo-optics video depicts the uniaxial extensional flow deformation

of a butyl rubber at 23°C being stretched at a Hencky strain rate

of 0.3 s-1 with a linear polarized halogen white light passing through

the mid-section of the sample. Note the uniform color evolution in the sample, evidence of

the uniformity of the applied extensional deformation.

This rheo-optics video depicts the uniaxial extensional flow deformation

of a butyl rubber at 23°C being stretched at a Hencky strain rate

of 0.3 s-1 with a linear polarized halogen white light passing through

the mid-section of the sample. Note the uniform color evolution in the sample, evidence of

the uniformity of the applied extensional deformation.

(AVI file format: 0.31 MB)

|

|

This rheo-optics video depicts stress relaxation of a butyl rubber at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 2.5.

Note how the stress fringes depict how the web of the sample relaxes non-uniformly from the center

of the sample towards its edges as it attempts to recoil from the applied deformation.

This rheo-optics video depicts stress relaxation of a butyl rubber at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 2.5.

Note how the stress fringes depict how the web of the sample relaxes non-uniformly from the center

of the sample towards its edges as it attempts to recoil from the applied deformation.

(AVI file format: 2.46 MB)

|

|

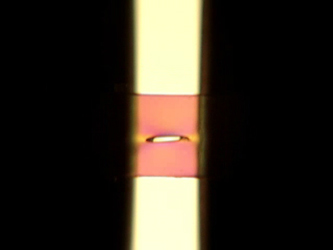

This rheo-optics video depicts stress relaxation of a butyl rubber sample

with a small entrapped bubble void in its center at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 1.

Note the stress fringe evolution around the bubble and how the bubble size remains stable during

relaxation.

This rheo-optics video depicts stress relaxation of a butyl rubber sample

with a small entrapped bubble void in its center at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 1.

Note the stress fringe evolution around the bubble and how the bubble size remains stable during

relaxation.

(AVI file format: 2.37 MB)

|

|

This rheo-optics video depicts stress relaxation of a butyl rubber sample

with an identical entrapped bubble void as the sample above at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 2.

Note how a critical strain is surpassed thereby driving bubble instability of the entrapped void and the eventual cleaving of the sample.

This rheo-optics video depicts stress relaxation of a butyl rubber sample

with an identical entrapped bubble void as the sample above at 23°C after being

stretched at a Hencky strain rate of 0.3 s-1 for a total applied Hencky strain of 2.

Note how a critical strain is surpassed thereby driving bubble instability of the entrapped void and the eventual cleaving of the sample.

(AVI file format: 1.97 MB)

|

|

|

|

This rheo-optics video depicts tensile elongation of a solid LLDPE sample

at 23°C stretched at a Hencky strain rate of 0.1 s-1 all the way to rupture.

This rheo-optics video depicts tensile elongation of a solid LLDPE sample

at 23°C stretched at a Hencky strain rate of 0.1 s-1 all the way to rupture.

(AVI file format: 3.44 MB)

|

|

|

With the use of a white light source, a fiber optic portal into the oven, and a high

temperature linear polarizer optical filter, rheo-optics measurements can also be made

on polymer melts within an oven chamber.

For instance, the simple experimental setup shown below depicting a model SER-HV-P01

mounted on an Anton Paar MCR host rotational rheometer

system equipped a CTD600 oven was used to capture the following

rheo-optics videos utilizing a reflector on the end

of a fiber optic cable to reflect white light off of the internal back surface of the oven

enclosure and a high-temperature linear polarizer filter mounted on the back side of the SER that was

used to polarize white light passing through the deforming sample and out the optical

window of the oven to the linear polarizer mounted on the video camera located outside

of the oven. The following videos depict parallel polarized light passing through the polymer melt

samples undergoing stretch.

|

|

|

|

This rheo-optics video depicts the uniaxial extensional flow deformation

of a molten HDPE sample

at a temperature of 129°C (just 0.8°C below its peak melt temperature) stretched at a

Hencky strain rate of 0.3 s-1. Note how the polymer sample remains perfectly

clear during the entire deformation, evidence that the sample is still molten. The type of

ductile fracture is also consistent with typical molten polymer behavior.

This rheo-optics video depicts the uniaxial extensional flow deformation

of a molten HDPE sample

at a temperature of 129°C (just 0.8°C below its peak melt temperature) stretched at a

Hencky strain rate of 0.3 s-1. Note how the polymer sample remains perfectly

clear during the entire deformation, evidence that the sample is still molten. The type of

ductile fracture is also consistent with typical molten polymer behavior.

(AVI file format: 0.65 MB)

|

|

This rheo-optics video depicts the uniaxial extensional flow deformation

of the same molten HDPE sample as above

at a temperature of 128.5°C (just 0.5°C cooler than the sample above) stretched at a

Hencky strain rate of 0.3 s-1. Note how the polymer sample becomes a bit cloudy

immediately upon deformation and gets darker as the deformation continues, evidence of a

quiescent flocculation of crystallites followed by a crystallization density increase with

increasing deformation. The state of the polymer sample is definitely solid-like as witnessed

by the type of fracture observed.

This rheo-optics video depicts the uniaxial extensional flow deformation

of the same molten HDPE sample as above

at a temperature of 128.5°C (just 0.5°C cooler than the sample above) stretched at a

Hencky strain rate of 0.3 s-1. Note how the polymer sample becomes a bit cloudy

immediately upon deformation and gets darker as the deformation continues, evidence of a

quiescent flocculation of crystallites followed by a crystallization density increase with

increasing deformation. The state of the polymer sample is definitely solid-like as witnessed

by the type of fracture observed.

(AVI file format: 0.77 MB)

|

|